Electric Power Generation From Kiln-Off Gases

By Narayana Jayaraman

1. Introduction

Waste Heat Recovery based power generation projects (WHR) in cement and lime plants are designed to capture the heat from the pyro-process off-gases to drive a thermodynamic cycle that operates a turbine and a generator. The thermodynamic cycle can utilize steam (Steam Rankine Cycle) or an organic fluid (Organic Rankine Cycle) as the operating medium.

2. Waste Heat Recovery Available for Power Generation

The most important task in designing the WHR system is to make the correct assessment of waste heat available for power generation. To this end, our consultants obtain the gas quantities and temperatures from the plant operating data and this information is then validated by comparing reported values and calculated values.

The heat required for other sections of the manufacturing process, such as drying of raw materials and coal, is carefully evaluated. ONLY the residual available heat is considered for power generation.

The moisture level of raw materials may not be constant throughout the year according to the season. The moisture’s monthly cycle and the corresponding heat requirement are evaluated to determine the optimum heat availability for sizing the WHR equipment. Choosing the maximum heat for sizing WHR equipment may render the entire project unviable economically, if for instance, the maximum quantity is available only for one month in a year.

3. Steam Rankine Cycle

The Steam Rankine Cycle (SRC) utilizes water as the thermodynamic fluid. The heat exchanger directly uses water and the heat is used for converting the water into high-pressure steam, which drives the turbine and the generator.

4. Organic Rankine Cycle

The Organic Rankine Cycle (ORC) uses an organic fluid to convert liquid to high pressure vapor which runs the turbine and the generator. However, due to the higher cost of the organic fluid and risk of exposing it directly to the hot gases, there is an intermediate thermal oil loop that collects the heat from the hot gases through a heat exchanger and delivers it to the thermodynamic fluid at the power plant.

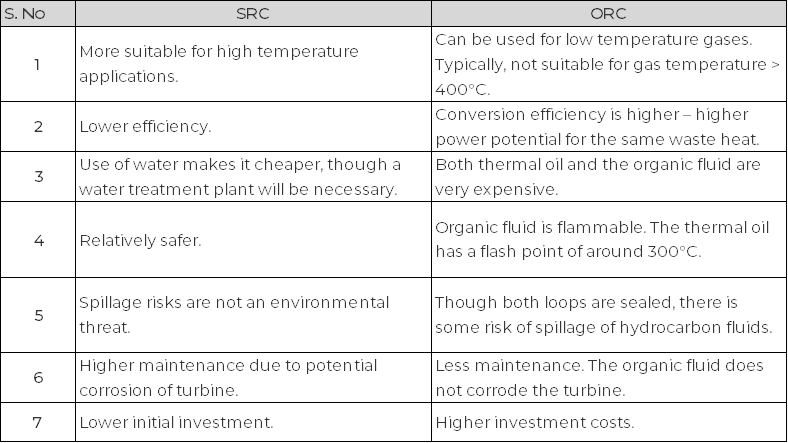

5. Brief Comparison between SRC and ORC

Table 1 gives a broad comparison of the two systems:

Table 1. Comparison Between SRC & ORC systems

Most plants expect a payback period of 5 years, which can happen only with high power tariffs (>0.10 $/kWh) and very favorable configurations (large kiln with high temperature gases) and much lower CapEx (~3-4 M $/MWe power). WHR projects are many times financially feasible if the Government provides a good incentive for waste heat utilization and for reducing the carbon footprint.

It is to be emphasized that the Owner requires an experienced consulting company having expertise in cement/lime process as well as WHR systems to truly evaluate opportunities and integrate designs with the existing plant operations.

PEC Consulting provides the crucial role of due diligence, choice of appropriate capacity and system, and engineering for integrating with the plant.

About the Author(s)

Narayana Jayaraman

Mr. Jayaraman has over 48 years of experience in the cement industry with expertise in plant conceptualization, layout, various operating systems, process calculations, production optimization, and Waste Heat Recovery (WHR) based power projects for cement and lime plants. He has led several studies to estimate realistic waste heat for power generation. He has had in-depth exposure to the technical, economic, and commercial aspects of large cement projects, and extensive experience in the upgrade and optimization of existing plants. He earned a BS in Mechanical Engineering from Osmania University, Hyderabad, India, and an MS in Mechanical Engineering from the Indian Institute of Technology, Kharagpur, India.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.