Essential Study Phases to Determine Project Feasibility

A project life cycle has several phases: Conceptual, Pre-feasibility, Feasibility, Financing, Engineering, Construction, Commissioning and Start up. In this article, we will focus on the first three phases which are essential to determine the project’s viability and to the successful outcome of the project’s implementation.

Project development phases should be followed in a certain order of coverage and extent to make necessary determinations before proceeding to the next more advanced phase. No tasks within a phase should be skipped or missed, and a phase should not be shifted to the next level until it is completely defined. The intent is to advance the project following a systematic course of action, starting with Phase 1, and within the steps and activities of each one of the phases. All along, there has to be a high level of commitment on the part of the Owner/Investor to follow the process in order to ensure the project’s viability in a realistic and objective way.

The evaluation of a potential project starts with an analysis and research of the existing information on the project. This initial conceptual work will support the next phases. During each progressive phase, the study will focus on more extensive investigation of the raw materials resources, market, infrastructure, community, and general project economics. The final phase will be completed when a level of certainty of the project’s viability can be determined at an acceptable risk level. The activities of each phase are summarized below.

PHASE 1 — CONCEPTUAL STUDY (ALSO CALLED “SCOPING STUDY”)

During this phase, the project is conceptualized based on the needs of the Owner. The Owner must appoint a single source of contact for the project with appropriate authority. The Owner’s Management Team must choose a qualified and experienced Consulting Company with the qualifications necessary to provide credibility on the findings and conclusions of the study. The following activities take place during Phase 1 – Conceptual Study:

- Analysis of the geology of each of the areas of interest and how they relate to potential mining operations.

- Raw materials resources of ample supply and quality must be identified by the initial geological survey.

- A market study to determine the processing capacities and help in the analysis of the economic viability of the projects.

- The market analysis will determine the size of production plant which would be economical within the area of influence.

- Permits must be considered along with any limitations that are likely based on local regulations.

- This will form the basis of the preliminary Environmental Impact Assessment (EIA).

- Development of mining and processing plant concepts with corresponding CapEx, OpEx, and an Economic Analysis.

- The Conceptual design must be performed taking into consideration:

- Plot Plan (plant layout at its physical location).

- Logistics (access to and from the facility).

- Infrastructure (utilities, natural gas, coal, process water, access).

- Block Flow Diagram (graphical representation of the plant process).

- CapEx (the plant’s cost – developed from references).

- OpEx (the plant operating costs – developed based on the location).

- Risk Analysis (outline of major risks and strategy).

- Definition of Environmental Standards and all permitting requirements.

- Preliminary Project Schedule.

The Conceptual Feasibility Study Report will provide a preliminary insight into the economic feasibility of the project.

PHASE 2 – PRELIMINARY (“PRE”) FEASIBILITY STUDY

The Pre-Feasibility Study is a more comprehensive study that determines the technical and economic viability of a mineral project. This phase refines the project as follows:

-

-

- Geological Exploration Program

- Extensive drilling and laboratory testing will be carried out as specified in the Conceptual Study Deliverables which will determine probable reserves of raw materials.

- Geological Exploration Program

-

Figure 1 – Full geological evaluation means detailed geological mapping based on core samples, and ultimately developing an economical mining plan

-

- Plant Site

- The site location and plant layouts are finalized.

- Plant Site

Figure 2 – Selected Site

- Market Analysis

- Further definition is given to projected sales for the eventual production.

- Technical Aspects

- Raw material adequacy assessment and calculations.

- Process evaluation of competing technologies.

- Project Design Criteria.

- Economic and Financial

- CapEx (plants costs are developed from budgetary vendor information).

- OpEx (operating costs are developed from refined location and plant design criteria).

- Economic Analysis.

- Market trends and future growth potential analysis.

- Organizational

- Assessment of support systems.

- Recommendations for functionality and efficiency improvements.

- Environmental and Social

- Environmental and regulatory compliance system development.

- Operating permit review (Federal, state and local agencies).

- Permits applications for all permits are filed.

- Public Relations consultant finalizes the assessment of social issues and a program to be implemented.

- Engineering analysis

- Plot Plan (defines the materials handling and process flow).

- Logistics (access to and from the facility is further refined).

- Equipment (an equipment list specific to quarry and plant is developed).

- Block Flow Diagram (the graphical plant process is refined).

- Risk Analysis (major risks are outlined).

- Strategy (the overall plant strategy is developed with a view to moving the project forward).

- Schedule (the Project Schedule is refined based on the changes and developments of the pre-feasibility study).

The Pre-Feasibility Study Report indicates if the project looks promising and has an attractive payback. The quarry and plant sites are now known, located in an area convenient in relation to the raw materials source and good logistics to the market. It will point out areas that need to be further refined.

Figure 1 shows a site where the ore geology is promising, as well as a good location for transportation and reasonable mining costs.

PHASE 3 – FEASIBILITY STUDY (ALSO CALLED “BANKABLE FEASIBILITY STUDY” AND “DEFINITIVE FEASIBILITY STUDY”)

A Feasibility Study will provide the information on the minerals reserves, infrastructure, and process designs which will serve as a basis for an investment decision and the support for project financing. During this phase, the development of the project reaches a high level of confidence.

The activities taking place during a Feasibility Study are as follows:

- Raw materials

- Mining plan to determine proven reserves.

- Plant Site

- The plant site location is refined.

- Market Analysis

- Final Market Study Report.

- Technical Aspects

- Process design to meet emissions standards.

- Fuel sources.

- Equipment List (Owner’s preferred equipment for upcoming firm equipment quotations)

- Construction Strategy

- Extent of the Owner’s participation is discussed. This raises further questions such as: will the savings of an EPCM project prevail, or will the project pay for passing the risk to a design-build contractor? Should the equipment supply be Owner purchased, and the construction design-build?

- Economic and Financial

- Integration of the technical and financial phases of the project The CapEx, OpEx and the logistics into the economic model for a realistic projection of the financials

- Environmental and Social

- Finalize filing of all necessary permit applications

- Finalize assessment of social issues

- Engineering Analysis

- Plot Plan (materials handling is developed and the plot plan revised accordingly)

- Logistics (all aspects of transportation and materials handling are valued)

- Equipment list (the equipment list is refined)

- Preliminary civil, structural, mechanical and electrical design is established

- Detailed Geotechnical Study

- Final Block Flow Diagram

- Equipment Bid Package(s) are issued, comprising:

- Design Criteria

- Equipment Specs

- Process Flow diagrams

- Electrical and Automation specifications

- Terms and Conditions

- Short list of construction companies. A Bill of Quantities is issued to obtain budgetary offers

- CapEx (update based on firm equipment pricing and budgetary contractor pricing)

- OpEx (update based on equipment selection and fuel and electrical budgetary quotes)

- Economic Analysis

- Risk Analysis (risk strategy is implemented in conjunction with each item in the CapEx, OpEx, and Market)

- Strategy (strategy to move the project to completion)

- Schedule (the Project Schedule is established based on strategy).

- Process Equipment Bidding

- The Owner provides materials samples for the process equipment bidders. The equipment bidder does the laboratory testing and provides confident performance guarantees that will meet all the necessary emissions standards.

- During the Feasibility stage, equipment bidders should have been able to respond to an RFQ in 12 weeks. The engineer’s technical bid evaluation period will depend on the number of bidders. Typically there is a period of clarification, checking and validation before the vendors are short-listed.

The Feasibility Study Report provides the Economic model required by the bank / external sources of finance. It provides professional financial projections and addresses the needs of investors and lenders.

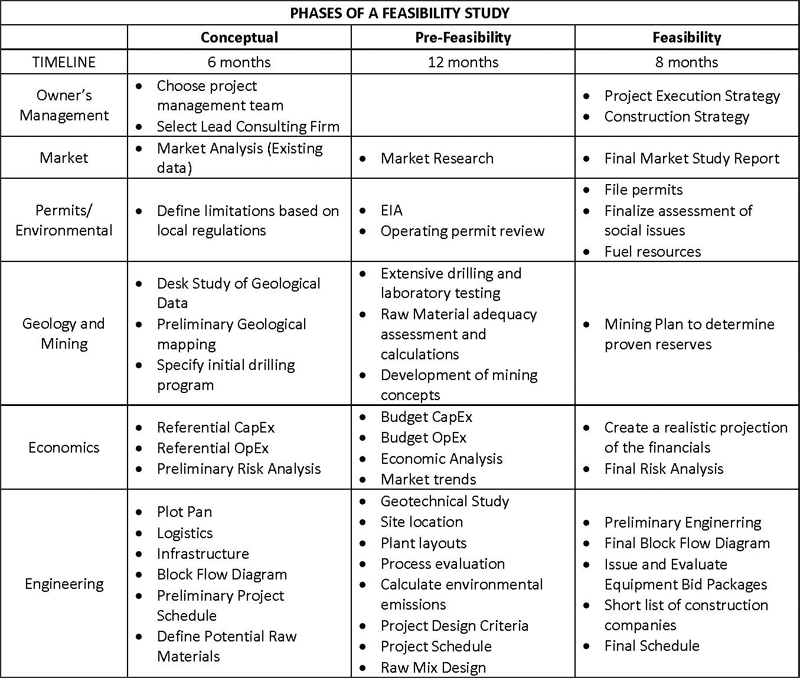

The following Figure is a table with a summary of Feasibility Study activites.

The main contributor to this feature article was Rita Merz, Business Development Manager at PEC Consulting Group.

View additional feature articles under Publications. Contact Us

Leave a Reply

Want to join the discussion?Feel free to contribute!