Constructability-Heart of the Project Costs

By Thomas W. Hedrick

Constructability review starts with the Original Equipment Manufacturer (OEM) contracts for equipment. Specifically, how many parts did the equipment price include? Where are these manufactured? What amount of site fabrication is required to assemble each machine? How complete was the equipment scope? This is the heart of the project cost, the sum of costs from the OEM, freight, site fabrication, and scheduled time to completion.

For the constructability topic, two actual projects, Project 1 and Project 2, are used as examples in this article. Both projects start with the purchase of equipment (OEM contracts) and end with a working Brownfield cement production facility constructed next to a working cement plant. The sites have reserves of good-quality raw materials, and there is an increased market demand for production. Often, the Client asks the Consultant what the Capital Cost (CapEx) and Schedule for the Project will be. The Client also needs a cash flow analysis of capital expenditures and needs to know when he can expect the new facility to start producing a saleable product to obtain a payback.

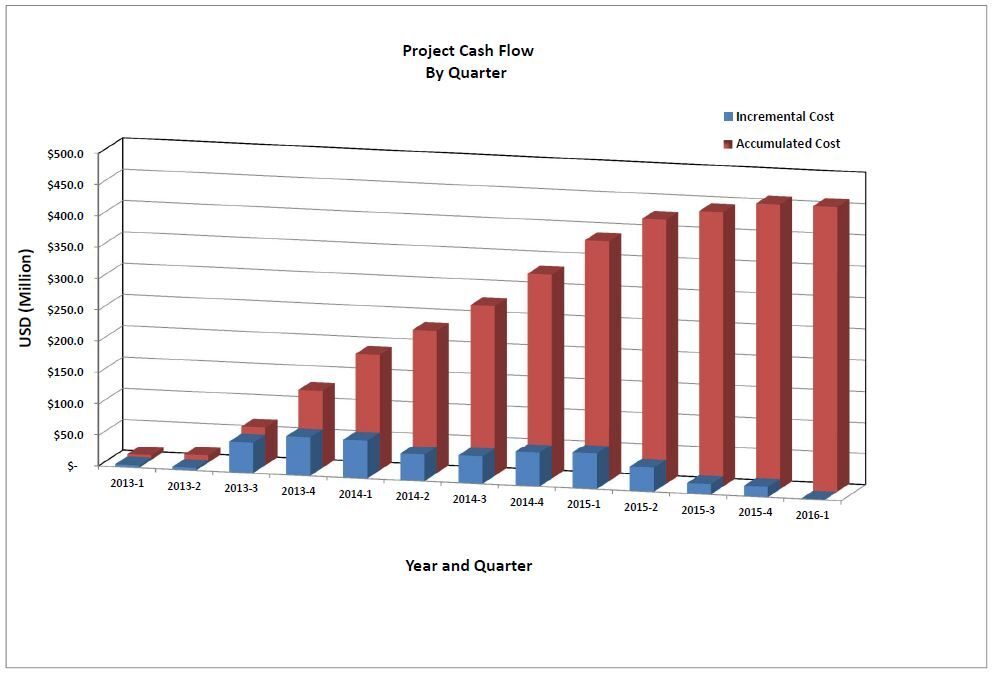

Figure 1 is an example of a project cash flow.

Figure 1. Example of Project Cash Flow, by Quarter

Typically, some engineering costs take place in the early part of the project development before the OEM vendors are contracted to supply the equipment. Elements that bear on the constructability for the OEM contract include:

- The number of pieces included in the project.

- For example: is the Kiln shell in 4 sections, or 40.

- The amount of field welding expected by the contractor.

- What length of welding is required, and what types and sizes?

- Are the anchor bolts by the OEM or contractor?

- Are the connecting bolts made by the OEM or contractor?

- The weight of the various sub-assemblies.

- Necessary in comparing various OEM suppliers.

- For logistics, we need to know the shipping weight.

- Contractor needs assembly lifting weights.

- The Country of origin of the fabrication.

- Important for logistics.

- Important for taxes.

- The number of pieces included in the project.

Note that the two projects in this article are real.

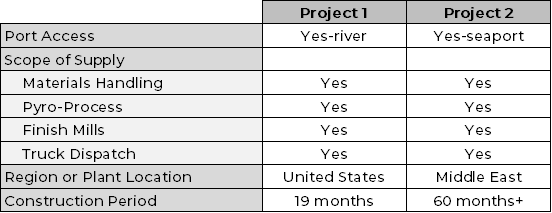

Figure 2. Differences in Projects

Figure 3 illustrates Project 1 preheater cyclones being transported from barge to a staging area.

Figure 3. Project 1-Site Transport from Water Transportation to Site Staging Area

On both projects, the structural design was started simultaneously with the OEM contract award. For Project 1, one of the first fabrication contracts was the pre-heater tower steel fabrication. For Project 2, the first contract was the pre-heater slip formed concrete design. The duration of engineering was approximately the same for both projects.

Figure 4 is of Project 2 during the slip-forming process. Both projects had slip-formed silos.

Figure 4. Project 2-Slip Forming the Homo Silo and Pre-Heater Structure

After the structural completion of the pre-heater, major vessels in Project 2 had to be elevated over the precast pre-heater and then erected into place.

Figure 5 is of Project 1 during construction of the pre-heater. One advantage of a structural steel pre-heater tower is that the pyro-process vessels can be erected simultaneously with the structural steel. The same figure illustrates that the contractor had the kiln placed on the kiln piers and the bag-house at the time the pre-heater tower was finishing off.

Figure 5. Project 1-During the Pre-Heater Construction

Site safety is affected by clutter and lack of proper sequencing of activities. Figure 6 is a photograph taken during the erection of the tertiary air duct on Project 1.

Figure 6. Construction of the Tertiary Air Duct

Figure 7 was taken during the alignment over the first kiln pier looking toward the preheater tower on Project 2.

Figure 7. Project 2-Looking Over Kiln Pier Towards Pre-Heater Tower

MSHA or OSHA safety officials would not allow the site clutter and violations as shown in Figure 8 of Project 2. Does safety pay? It certainly was evident with Project 1, which maintained the predicted schedule throughout its duration without time loss due to accidents.

Figure 8. Pre-Heater Foundation Formwork

Throughout Project 2, there is heavy presence of fixed scaffolds. As noted in figure 9, the utilization of many man-lifts is customary in the U.S.

Figure 9. A Very Minimal Amount of Scaffold Was Used. Man Lifts Are Very Prevalent

Figure 10 is uncluttered because the mason used an elevated scaffold. Primarily, this keeps the work height relative to each mason, which is ideal for productivity.

Figure 10. Elevating Scaffold Keeps the Masons at Ideal Working Elevation

Fixed scaffolding cannot keep masons at the ideal height but, as Figure 11 from Project 2 illustrates, ramps for the hod carriers do make for efficient delivery when a high-lift fork lift is not in use.

Figure 11. Project 2-Masonry Scaffold With Ramps for Efficient Work Height

We have looked briefly at two projects. Does scaffolding, project safety, or type of forming define a short or long schedule? Is there magic in a steel vs. a concrete pre-heater structure? Only to an incremental degree. When performing a constructability review, we consider how well the integration of OEM supply is to the engineering; the structural plans are thus available for bidding on time and the logistics, both to and through the site, are taken into consideration. Are the laydown areas really just that, or are they pre-assembly areas that would have been better served at the OEM’s location than at the construction site?

We look for innovation like in Figure 12, where the existing primary crusher operates throughout a retaining wall construction using gabions to maintain a wide and safe ramp for quarry feed stone. We look for realistic delivery schedules and integrated structures with the mechanical OEM equipment. We look for power to be installed and ready for use prior to commissioning.

Figure 12. Project 1-Contractor Used Rock Gabions For Retaining Walls

Experienced planning and a team that starts with the first cost equipment will result in a realistic and short construction schedule. Remember that the owner will not see a return on investment (ROI) until the plant is operating efficiently. The Constructability Review will definitely increase the ROI.

Which Owner will you be? As in Project 1, with a schedule completed in 19 months, or will you still be looking at construction costs 60 months later and wondering if you will ever produce? PEC Consulting’s staff has extensive experience on Constructability Reviews and stands by to assist you.

About the Author(s)

Thomas W. Hedrick, P.E.

Mr. Hedrick is a Senior Project Consultant at PEC Consulting Group. He specializes in materials handling, has been in manufacturing and engineering for 40 years, holds seven U.S. patents, and has written several dozen technical papers for various magazines and conferences around the world. Mr. Hedrick maintains a passion for excellence in client relations and project execution.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.