Frac Sand Dryer to Power Generator

By Timothy E. Dudash and Thomas W. Hedrick

Would you like to have free heat for your Proppant sand dryer; or free electric power? Actually, these are related and you may be a candidate for substituting the hot gas generator for your sand dryer with a gas turbine generator.

A good candidate for this application is a sand plant that operates around the clock, year round. The closer your manufacturing process is to full utilization, the more likely you are to economically generate your own electric power and to routing and conditioning the exhaust gas from the generator to your sand drying process for an overall savings in plant energy costs.

Figure 1. Mars 100, Gas Turbine Generator Set

1. Case Study

The case study takes the following considerations:

- Cost of power from the grid: $0.07 KW/h.

- For off-hours, in a permitted co-generator situation, the State mandates a $0.04 KW/h buyback rate by the utility.

- Natural gas (NG) is used for the drying process; however, since the cost of gas is unpredictable, we developed a payback analysis of a range of NG costs.

- The moisture content of the sand varies between 3 and 6%.

The plant processes between 250 and 300 tph of wet sand, controlled largely by the heat available from the hot gas generator. A Caterpillar Mars 100 gas turbine, capable of producing just over 11 KWe was selected, with an available exhaust energy of 75.3 MMBtu/h, nicely matching the dryer system needs.

Capital cost for the power plant included the installed equipment, as well as electrical switchgear to allow power to be distributed throughout the plant. Plant power needs were about 50% of the output, but a neighboring production line could easily use the remaining power.

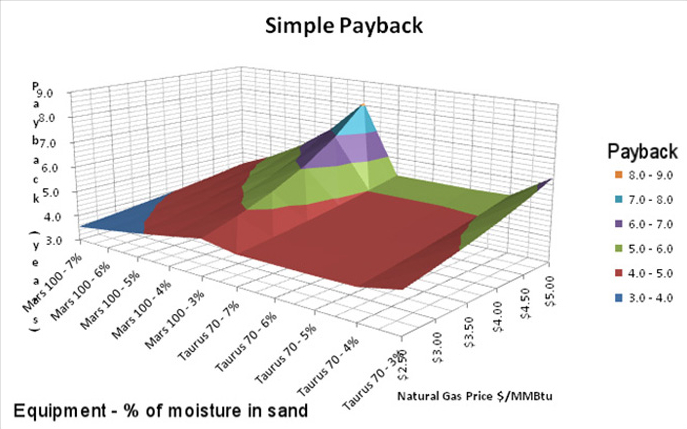

Payback is best explained graphically. Figure 2 shows payback for the system that occurred in 4 – 5 years for gas pricing over a wide cost range.

Figure 2. Payback of Two Caterpillar Generator Models; With Various Fuel Costs

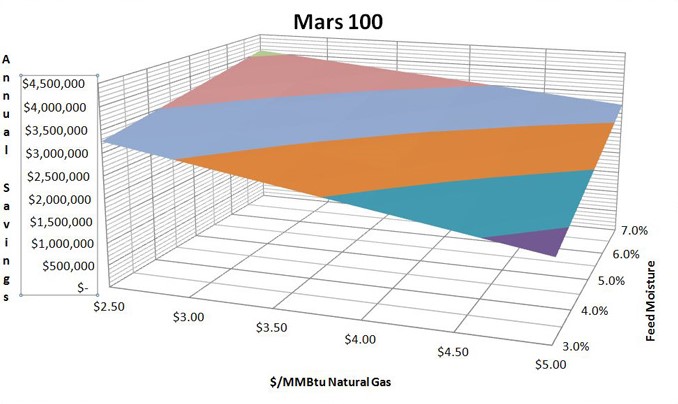

Additionally, the heat output of the generator set was higher than the current hot gas generator, so the ability to run the dryer circuit at maximum volume was fully assured. Heat availability is better illustrated in Figure 3 where the moisture content was fully investigated.

Figure 3. Feed Moisture and NG Cost Variation Related to Annual Savings

Each plant is of course different. Some operators would love to have $0.07 KWh power; others do not operate nearly the full year, or around the clock. Some States do not mandate that utilities buy back the extra power from a co-generation plant. This is a simple application of waste heat recovery that a technical feasibility study can fully examine.

However, most mine operators are comfortable to utilize Caterpillar equipment, and Caterpillar offers their systems with complete maintenance contracts and financing. It is hard to argue with the energy efficiency of this application.

About the Author(s)

Timothy E. Dudash

Mr. Dudash is a Process Engineer at PENTA Engineering Co. He has experience in the minerals industry and has spent many years commissioning mechanical systems in the western hemisphere. Feasibility, system payback analysis, and optimization are his special interests.

Thomas W. Hedrick

Mr. Hedrick, P.E. is a Senior Project Consultant at PEC Consulting Group. He specializes in materials handling, has been in manufacturing and engineering for 40 years, holds seven U.S. patents, and has written several dozen technical papers for various magazines and conferences around the world. Mr. Hedrick maintains a passion for excellence in client relations and project execution.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.