Quick Lime and By-Products

By Pompeyo D. Rios

1. Metallurgical

The largest use of lime is in steel manufacturing, where it serves as a flux to remove impurities (silica, phosphorus, and sulfur). Lime is used in basic oxygen furnaces and electric arc furnaces, as well as in secondary refining.

1.1. Iron & Steel

High calcium and dolomitic limes are used extensively as a flux in purifying steel in the traditional basic oxygen furnace (BOF) and the newer electric arc furnace (EAF). In the BOF, the lime factor per ton of steel averages 150 lb/ton, while in the EAF, the factor is 85 lb/ton. Lime is very effective in removing phosphorus, sulfur, silica, and, to a lesser extent, manganese. The higher the silica and phosphorus content in the iron ore, the higher the quicklime consumption.

1.2. Nonferrous Metallurgy

Lime is also essential in the production of non-ferrous metals. For example, quicklime is used to remove silica from bauxite ore and for causticization in the manufacturing of alumina. Dolomitic quicklime is used to produce metallic magnesium by thermal reduction which reduces magnesium oxide. Lime is also used in the processing of ores and the subsequent smelting and refining of copper, zinc, lead, and other nonferrous ores.

2. Environmental

The use of lime to address environmental problems is one of the fastest growing markets for lime products. Lime is used in almost every area of pollution prevention, including treatment of air emissions, treatment of drinking water and waste waters, and remediation of hazardous wastes.

2.1. Flue Gas Desulfurization

2.1.1. Flue Gas Treatment

Lime is used to remove sulfur dioxide (SO2) and hydrogen chloride (HCL) from flue gases. SO2 removal efficiencies using lime scrubbers range from 80 to 99% at electric generation plants. HCL removal efficiencies using lime range from 30 to 50% at municipal waste to energy plants1.

2.1.2. Mercury Removal

There are many methods for controlling mercury emissions. One control technology currently being evaluated is using hydrated lime together with activated carbon to capture mercury in the off-gases from power plants and pyro-processing industries.

2.2. Water Treatment

2.2.1. Drinking Water Treatment

Lime is the main chemical used in the treatment of potable and industrial water.

- Water Softening: Hardness caused by bicarbonate and carbonate of calcium and magnesium is removed by using hydrated lime. Hardness caused by other calcium and magnesium salts is removed by using soda ash.

- PH Adjustment: Hydrated lime is used to adjust the pH of water to prepare it for further treatment. Lime is also used to fight “red water” by neutralizing acid water, therefore reducing corrosion in pipes.

- Pathogen Growth: Lime prevents the growth of bacteria and some viruses by controlling the water pH between 10.5 and 11.

- Removal of Impurities: dolomitic lime is used to remove silica. Lime is also used to remove manganese, fluoride, and iron.

2.2.2. Wastewater Treatment

Lime is extensively used in industrial and municipal water treatment.

- Municipal Water Treatment: Lime precipitation is used to prevent eutrophication (algae build-up) on the water surface by precipitating phosphorous and other suspended and dissolved solids. In the process of coagulation, alum, and ferric chloride are used to lower the pH. Lime is used to counteract the pH level and allow efficient nitrogen removal.

- Industrial Wastewater: Lime is used to neutralize sulfuric acid in steel plants where the iron salts are precipitated. Lime also neutralizes and precipitates chrome, copper, and heavy metals in the treatment of water discharged from plating plants.

2.2.3. Acid Mine Drainage

Lime is used to neutralize highly acidic drainage from mines. Lime is also used in coal washing plants to reduce equipment corrosion.

2.3. Sludge Treatment

Quicklime and calcium hydroxide are widely used and are a cost-effective option to treat biological wastes. The lime injection helps control the environment to prevent the growth of pathogens in wastewater sludge like biosolids and convert sludge into a usable product. Below are the Chemical reactions on biological waste treatment:

- Calcium hydroxide creates a high alkaline compound with a pH as high as 12.4. At pH levels above 12, the cell membranes of harmful pathogens are destroyed. The high pH also prevents flies and other insects from infecting treated biological wastes.

- Quicklime injection creates an exothermic reaction, increasing the temperature to 70°C, which provides pasteurization that meets EPA’s Class A requirements.

- The high pH will precipitate most metals present in the waste and reduce the solubility. It also provides free calcium ions that react with odorous sulfur, destroying the waste odor.

- Adding lime also increases the solid content of the waste, making it easier to handle.

Lime-treated biosolids are safe and promote recycling. As EPA notes, “properly prepared biosolids provide a rich source of essential fertilizer elements needed by plants to produce food.” Animal Wastes- Excessive buildup of animal waste creates an excess of phosphorus and nitrogen, which cannot be absorbed by the soil. The addition of hydrated lime to animal manure converts manure to a usable form of fertilizer that contains the correct amount of nutrients, which can be absorbed into the soil and used by plants. Hydrated lime also aids in destroying odors, especially hydrogen sulfide odors, which result from the accumulation of large quantities of manure. Currently, lime is not widely used to treat animal sludge, but it can offer a practical and economical option.

3. Chemical and Industrial Uses

3.1. Agricultural Lime and Fertilizer

Hydrated lime balances soil pH for proper plant growth and nutrient intake by neutralizing garden soils. Many plants cannot tolerate acidic soils and prefer soil conditions that are neutral to slightly alkaline, pH between 6 and 7.

Lime in the US has been substituted by ground calcium carbonate; however, in Europe hydrated lime is used in conjunction with nitrogen fertilizers reduces the use of fertilizer.

3.2. Glass

A glass batch is composed of approximately 70% sand, 18% soda ash, and 12% lime, usually in the form of dolomitic lime.

3.3. Paper and Pulp

Lime is an important additive in the papermaking industry; however, a shift from acidic to an alkaline process has changed levels of consumption as noted below:

3.3.1. Sulfate Process

The largest application of lime in pulp manufacturing is as a causticizing agent in sulfate (Kraft) plants. Wasted sodium carbonate is then reacted with high calcium lime to generate caustic soda for reuse in the process. Plants are able to recover about 90-98%2 of the lime by dewatering the waste calcium carbonate mud, then re-calcining it in rotary kilns.

3.3.2. Sulfite Process

Plants using the sulfite process consumed large quantities of quicklime for the preparation of the calcium bisulfite liquor capable of dissolving the noncellulosic wood elements. This process is disappearing due to waste disposal problems.

3.3.3. Bleaching

Lime is used as a bleaching agent for pulp.

3.4. Precipitated Calcium Carbonate (PPC)

PCC is use as a filler and coating pigment for premium quality paper enhancing the brightness, color, smoothness, and bulk of the paper, replacing more expensive paper pulp. Approximately 75%3 of worldwide PCC production is used in the paper industry.

PCC is also used as a plastic additive, white paint pigment, putty, sealer, and adhesive ingredient. It is also an important ingredient in toothpaste.

3.5. Sugar Refining

Hydrated Lime is used in the production of sugar from both sugar cane and sugar beet. Approximately 200 kg of lime is required to produce one ton of beet sugar, and about 10 kg is required for one ton of cane sugar.

Crude sugar juice (sucrose) is treated with lime to raise the pH and to precipitate calcium salts of organic and inorganic acids. These insoluble compounds are filtered. Carbon dioxide is then passed through the suspension to precipitate excess lime as calcium carbonate. Precipitated carbonate sludge is filtered out. This process can be repeated several times in order to achieve greater purity of the sugar solution.

4. Construction

4.1. Asphalt

Hydrated lime acts as a mineral filler by stiffening the asphalt binder in hot mix asphalt (HMA), improving resistance to fracture, altering oxidation kinetics and interacting with products of oxidation to reduce their effects.

4.2. Building Uses

Hydrated Lime is added to cement and sand to create mortar with superior strength and low water permeability. Hydrated Lime is also used as an ingredient in stuccos and plasters, enhancing strength, durability and workability of these materials.

4.3. Soils Stabilization

Quicklime and hydrated lime can significantly improve subgrade engineering properties by increasing the stability, impermeability, and load bearing capacity of the subgrade. It is extensively used in soil stabilization beneath roads and similar construction projects. Quicklime is also used to dry wet soils at construction sites.

4.3. Other Construction

Lime is used with pozzolans and Portland cement in the manufacturing of lightweight cellular concrete products.

4. Construction

Refractory dolomite is manufactured with dolomitic lime. Iron oxides are added to stabilize the resulting hard-burned quicklime against decomposition from moisture. This material is used to make refractory bricks.

Silica Bricks, used for lining furnaces, are made by mixing ground silica with 1 to 3% milk of lime.

5. The U.S. Market

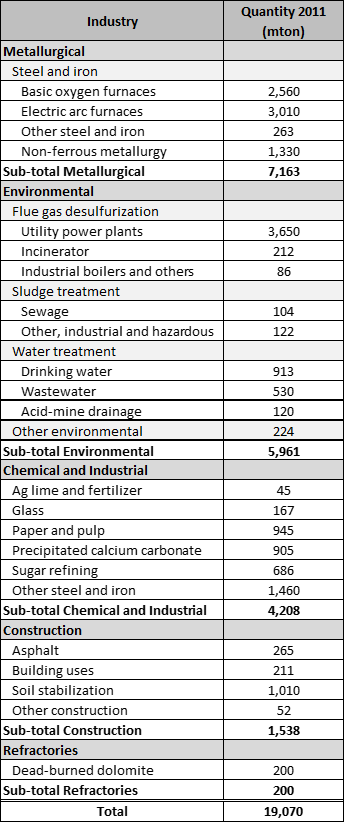

In 2012, an estimated 19.54 million metric tons of quicklime and hydrated lime were produced in the U.S. The approximate breakdown of lime consumption by general end-use sectors was as follows: 38% for metallurgical uses, 31% for environmental uses, 22% for chemical and industrial uses, 8% for construction uses, and 1% for refractory dolomite (see Table 1).

Commercial sales accounted for 91% of total lime consumption and 92% of domestic production. Captive lime accounted for the remainder of consumption and was used in the production of steel in basic oxygen furnaces (BOF), magnesia production, precipitated calcium carbonate production, sugar refining, and refractories (dead-burned dolomite). The data on captive lime consumption are withheld to avoid disclosing company proprietary information, so Table 1 only shows the application of lime for commercial uses.

Table 1. Lime Use by Producer 5

Note. Adapted from USGS (2011). Minerals Yearbook, Lime.

References

- 1 National Lime Association – Environmental Uses, Flue Gas Treatment.

- 2 Lime Fact bulletin, National Lime Association, Pulp and Paper.

- 3 Lime Fact bulletin, National Lime Association, Precipitated Calcium Carbonate.

- 4 USGS Mineral Commodity Summaries, January 2013.

- 5 USGS 2011 Minerals Yearbook, Lime.

About the Author(s)

Pompeyo D. Rios

The extent of Mr. Rios’ experience encompasses the design and successful project management of heavy and light industrial plants, both domestic and foreign, including mineral processing facilities and cement and lime plants. He has been responsible for the preliminary layout and detailed engineering of grinding facilities, cement, and lime pyro-processing systems, coal grinding and firing systems, material handling systems, and crushing and screening facilities. He holds a BS in Mechanical Engineering from the Universidad Metropolitana, Caracas, Venezuela, and a Master in Business Administration, Information Systems and Finance/Accounting from Regis University, Denver, CO.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.