Reclaiming from Mineral Stockpiles

By Thomas W. Hedrick

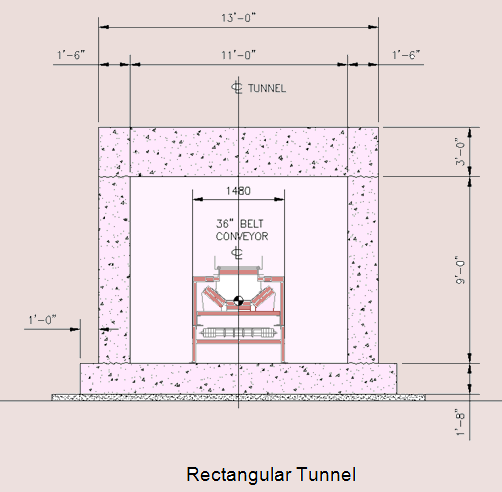

A very common feature in minerals plants is the materials handling tunnel. Most tunnels are rectangular because the cement finisher has forms for this type of structure. However, from the point of view of a structural engineer (see figure 1), this is a very inefficient type of load carrying system. The top and bottom (foundation) of the tunnel is quite thick because they must span across the tunnel width as a simple beam This beam action means the designer keeps these members thick, using more rebar and concrete than the alternative, the arched tunnel.

Figure 1. Rectangular Tunnel

Note. A simple rectangular tunnel with a 36″ standard troughed conveyor with access on both sides requires an 11 ft. tunnel width.

The thickness of the shell wall is to allow some anchorage for the moment transfer of the roof around to the side of the box culvert (rectangular section) This is generally a lightly reinforced section. By this we mean that the amount of steel per cubic yard of concrete is closer 200 lbs than 400 lbs per cubic yard.

The alternative section is the arched section shown in Figure 2. The inside dimensions are the same (11’ wide by 9 feet high) in both figures. The thickness of the shell walls however are considerably thinner in the arched tunnel. You will recognize the shape of this tunnel if you are a student of older masonry arch structures. Many of these tunnels were built with no mortar, and just a keystone at the center top to provide stability in all directions. This arched tunnel uses about 1/3 of the concrete that the rectangular tunnel needs, and is a lightly reinforced section (about 175 lbs per cubic yard of concrete).

Figure 2. Arched Tunnel

Note. An arched tunnel with the same interior dimensions as the rectangular tunnel in Figure 1

Figure 3 shows a view of an arched tunnel from the inside of the tunnel. Using a Kynar type of urethane high gloss paint will provide a very bright surface to the inside of the tunnel, as well as a place to screw the electrical conduit and junction boxes prior to the shotcrete process on the outside of the arch.

These tunnels are easy to slope, providing a good drainage method for any stray water that gets into the structural system.

Figure 3. Arched Tunnel Using Gage Metal

Note. This arched tunnel is formed using gage metal, formed in and seamed together to support the concrete (shotcrete) roof.

Figure 4 is a photo from the exterior of the tunnel. A curb will be used at the feeder openings to form up the rough openings for the feeders. Shotcrete is a very dense form of concrete; however, some customers also coat the exterior surface with a waterproofing mastic for additional protection against moisture.

Figure 4. Exterior of the Tunnel

Note. Shotcrete top surface of the tunnel, with the rough openings showing where the feeder points will be located.

The typical cost of an arched tunnel is about half the cost of a rectangular tunnel. Many contractors use the seamless roofing shown here. Others will inflate a reusable membrane. The larger (longer) the project, the less the unit cost will tend to be. Typical uses for these tunnels are all types of bulk materials reclaim, including:

- Coal.

- Coke.

- Cement Clinker.

- Limestone.

- Pebble Lime.

- Wooden Pellets.

- Ores.

- Frac (Proppant).

- Sand.

Basically, if the material will flow through a feeder, this type of tunnel is appropriate.

About the Author(s)

Thomas W. Hedrick

Mr. Hedrick, P.E. is a Senior Project Consultant at PEC Consulting Group. He specializes in materials handling, has been in manufacturing and engineering for 40 years, holds seven U.S. patents, and has written several dozen technical papers for various magazines and conferences around the world. Mr. Hedrick maintains a passion for excellence in client relations and project execution.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.