Waste Heat Recovery for Power Generation

By Francisco M. Benavides

Hot process gases that are vented to the atmosphere by a Process Plant represent a potential for the generation of electric power. The installation of a Waste Heat Recovery (WHR) System is a “green” option that must be considered.

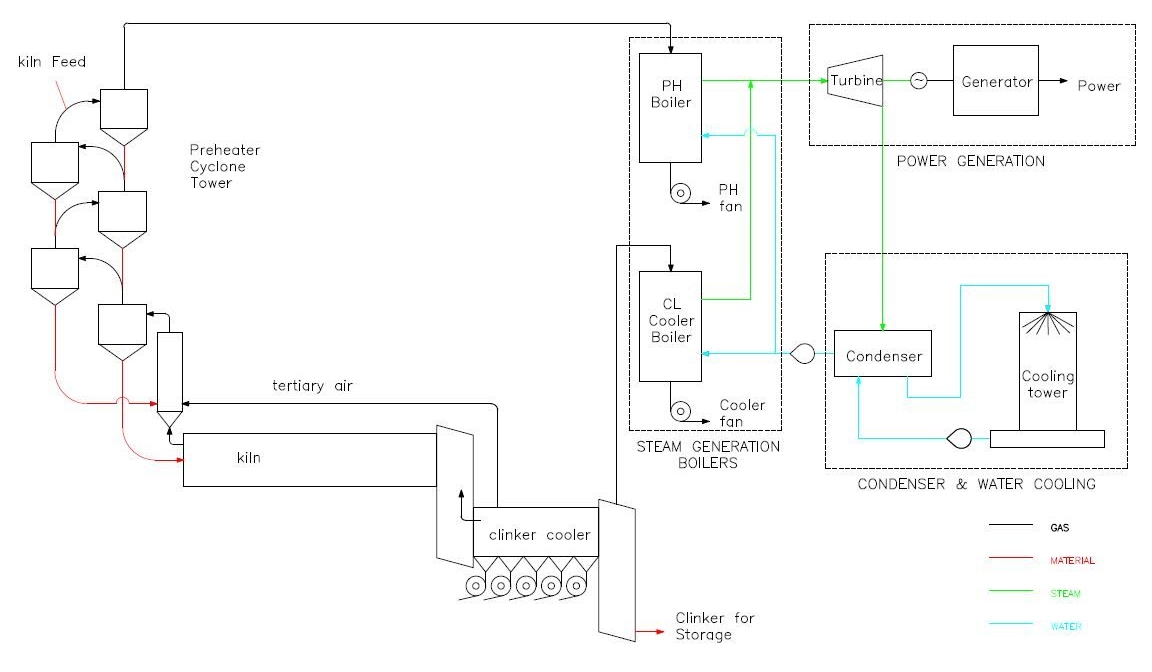

Figure 1. Typical WHR System

The Waste Heat Recovery (WHR) System consists of a steam generation unit and a power generation unit. The steam generation unit is a set of boilers placed in the path of the waste gases. The heat in the gases, sometimes supplemented by additional heat in the co- generation process, is used for generating steam. The steam can be used for other process requirements within the industrial plant, or used for driving a turbine that is connected to the generator. The generated power can either be used for running plant equipment or fed back to the power grid.

The recovered waste heat represents “green energy” since it is a direct savings in the use of fossil fuels with the consequent reduction of carbon dioxide emissions. Furthermore, cooling of the process gases is done without wasting scarce water or diluting with ambient air that would increase the energy consumption of the fans.

Several challenges exist, such as sticky and abrasive dust in the gas, or corrosive vapors such as SO2. The boiler must be custom-designed carefully to handle the specific characteristics of the off-gases. In special cases, like when there is a low gas temperature, an Organic Rankine cycle can be chosen instead of the steam cycle. The recovered waste heat represents “green energy” since it is a direct savings in the use of fossil fuels with the consequent reduction of carbon dioxide emissions. Furthermore, cooling of the process gases is done without wasting scarce water or diluting with ambient air that would increase the energy consumption of the fans.

Figure 2. Waste Heat Recovery System

PEC Consulting’s feasibility studies evaluate the characteristics of the process plant’s off-gases and assess the quantity of heat that can be usefully recovered. PEC Consulting will evaluate space limitations and find a solution to place the boilers and power generation system and integrate new equipment with the existing. PEC Consulting’s feasibility studies provide the client with an assessment of the power potential, a financial analysis with capital and operating cost estimates, and a layout to integrate the Waste Heat Recovery System with the existing process plant.

Waste Heat Recovery (WHR) Systems help process industries to become part of the green revolution by conserving natural resources. In addition to providing a reliable electrical supply, the reduction of the carbon footprint helps the environment. A co-generation plant is also a great benefit when the power grid supplying the plant is unreliable or when the plant is subject to interruptible power.

PEC Consulting can help the process industries with the realization of this noble and profitable goal.

About the Author(s)

Francisco M. Benavides, P.E.

Mr. Benavides, Principal Consultant at PEC Consulting Group LLC, has many years of experience in project management, design and construction. He has conducted bankable feasibility studies, economic analysis of mineral transport alternatives, plant valuations for acquisitions and for financing purposes, and due diligence studies. He holds an MBA from Kellogg School of Management, Northwestern University, Evanston, Illinois; a Bachelor of Science and Professional Degree in Civil Engineering from the Missouri University of Science & Technology, Rolla, Missouri; and has completed Graduate Studies in Engineering Management and Environmental Engineering at Missouri University of Science & Technology.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.