Cement Industry – Plant Process Audits

By Narayana Jayaraman

A Plant Process Audit is a comprehensive evaluation of the overall performance of the plant’s operations. PEC Consulting systematically evaluates the plant’s operations, identifies the areas that are not working efficiently, and presents its findings and solutions to optimize the plant.

1. Steps for Process Audits

1.1. Benchmarking

Modern, dry-process cement plants with efficient configuration of grinding and pyro processing systems typically consume less than 700 kcal/kg-cl thermal energy and 100 kWh/mt of electrical energy. Older plants have inefficient systems, which compounded with operational and maintenance inadequacies, tend to have much higher energy consumption. Based on the plant’s conditions and specific requirements, general benchmarking is done to set targets. Plant audits evaluate the operation of a cement plant against the appropriate benchmark. After a detailed evaluation, recommendations for plant optimization are made in three levels of capital investment:

- Step 1: None or very little capital investment — by making adjustments to the operational protocols and improving maintenance.

- Step 2: Minor capital investments – with payback within 24 months..

- Step 3: Major capital investments – with 3- to 5-year payback.

1.2. Historic Evaluation

The plant operational and stoppage data is collected over the past two or more years. The reasons for the stoppages are analyzed in terms of category (mechanical/electrical/instrumentation/refractory/other), duration, and frequency in order to identify causes in order of severity.

The plant performance is also analyzed by department. Often a department’s best performance does not occur at the same time of the best performance of the plant as a whole. If we choose the best performance times of each department and make them occur at the same time, the plant performance would show a considerably higher level of efficiency. Attempts are made to make them happen at the same time, which is not an unrealistic target as the departments had indeed performed at that level in the past.

Through a systematic approach, all departments are made to perform at the highest possible level thus increasing the plant’s overall productivity.

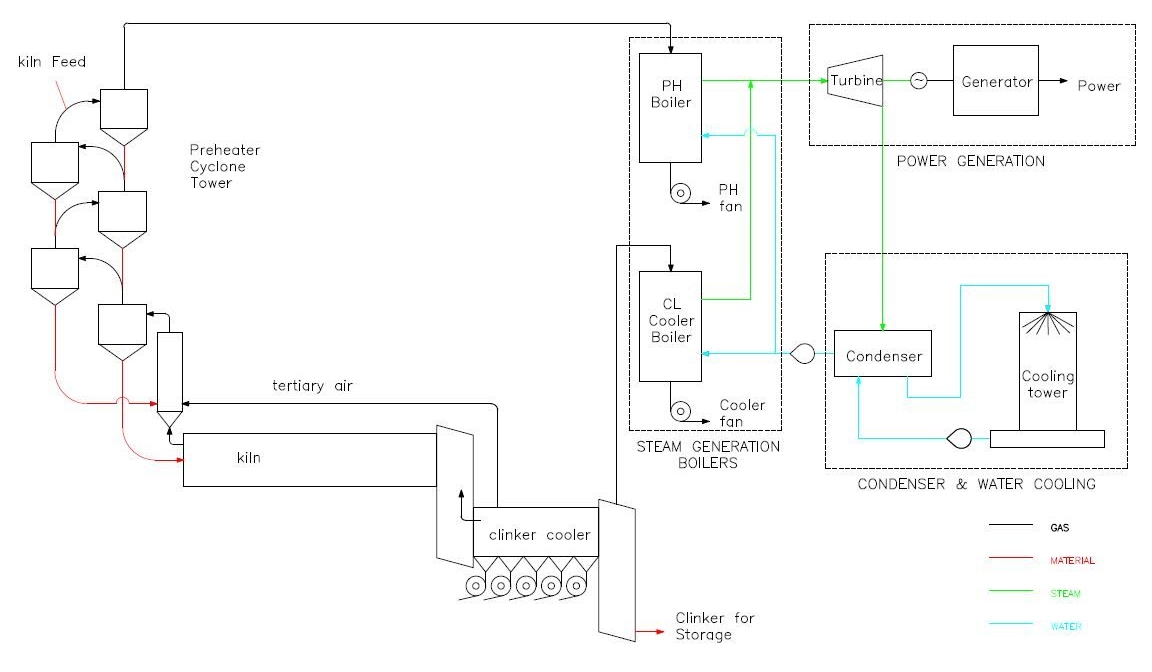

1.3. Thermal Energy

Thermal energy relates to the Pyroprocessing system. For a 1 million mt/year clinker production, savings of 10 kcal/kg-cl would result in annual savings of approximately $185,000.

(1,000,000 tpy*1,000 kg/y*10 kcal/yr * $120/t-coal)

(6,500kcal/kg-coal/1,000 t coal)

Another significant advantage in most cases is that the reduction in heat consumption can be utilized to increase production.

Potential savings can also be derived from:

- Cooler optimization.

- Arresting in-leakages.

- Optimization of operational strategy.

1.4. Electrical Energy

Large fans and mill drives are major consumers of electrical energy.

- Fans: fan power is linked to specific heat consumption and many operational parameters. Optimization of these parameters will help lowering fan power consumption.

- Mills: in the case of ball mills, optimization of the mill charge and upkeep of the mill internals will minimize power consumption. As for vertical roller mills, the inspection of mill internals and separator and adjustments in the operation will bring about improvements in energy consumption and production increase.

1.5. Chemistry and Operations Strategy

Clinker quality related issues are addressed by evaluating the chemistry and operational parameters.

1.6. Emissions Management

The inadequacy of emission management systems generally found in older plants does not meet current emission regulations. PEC Consulting can analyze emission levels and provide solutions to improve emission management.

The expert staff at PEC Consulting Group has the capability to undertake Plant Process Audits and provide ongoing technical assistance to cement plants to improve operational performance. The scope of work generally includes:

- Plant visit and discussions with the plant’s operating personnel.

- Data collection of historical stoppages and operating parameters.

- Analysis of the data to identify areas for improvement.

- Submission of a report providing observations and recommendations, including economic analysis to establish the cost/benefit ratios.

- Develop an implementation program with the Plant Management.

- Work with Operating personnel through periodic goal-setting and audits until the prescribed performance goals are achieved.

A Plant Audit is the foundation to optimize the plant operations and often presents the lowest cost/benefit investment ratio.

About the Author(s)

Narayana Jayaraman

Mr. Jayaraman is PEC’s expert on cement process systems; he has over 45 years of experience in the cement industry. His expertise includes the process of white cement plants, including upgrading the capacity and resolving process issues at two cement manufacturing facilities in India. He has had in-depth exposure to the technical, economic, and commercial aspects of large cement projects and extensive experience in upgrading and optimizing existing plants. He earned a BS in Mechanical Engineering from Osmania University, Hyderabad, India, and an MS in Mechanical Engineering from the Indian Institute of Technology, Kharagpur, India.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.