Cement Import Distribution Terminals

By Christian A. Benavides

1. Cement Import Terminal Scoping Study

For the implementation of a new Cement Import Terminal, the best practice begins with hiring an experienced consultant to perform a Feasibility Study. As a preliminary step, prior to beginning the feasibility study, a scoping study should be executed. The Scoping Study will examine the fundamental aspects to the project.

The Scoping Study should focus on:

-

- Preliminary Communications with Port Authority and Government Agencies.

- Permitting.

- Preliminary FOB Cement FOB Pricing for Region and Availability.

- Examination of Possible Site/s location/s.

- Preliminary Project CapEx, OpEx, Simple Economic Analysis.

- Preliminary Conceptual Designs.

- Preliminary Examination of Infrastructure and Logistics.

- Social and Environmental hurdles.

- Market Study (if applicable).

The Feasibility will advance elements of the Scoping Study and will additionally cover:

-

- Source pricing to Cement Supply and Transport.

- Obtaining bids from Vendors and Contractors.

- Develop Design Criteria, Basic Layouts and Specifications for the Port Facility terminal.

- Project Schedule and Execution Strategy.

- Risk Assessment.

- ROI.

The primary role of the Consultant will be to gather and analyze the data for the Study, while the Owner takes an active role in advancing communications with all relevant stakeholders and consultants, which may include the following:

Port Authority

Local Government Agencies

-

- Consultants.

- Legal Counsel.

- Vendors/Contractors.

- Cement Suppliers.

- Transport Companies.

- Unions/Stevedores.

2. Facility Sizing and Design for Optimization

In order to optimize operations to improve margins per ton of cement, it’s important to understand all the variables. These variables need to be examined and weighed against each other to determine the best facility type, size and level of automation. The variables considered include:

-

- Cement Shipment Size.

- Product Turnover .

- izing of Unloading Equipment.

- Storage Size Requirements.

- Facility lot Size and Berth Capabilities.

- Port Ship Size Limitations.

- Port Fees.

- Maintaining Separation of Deliveries.

- CapEx, OpEx, and Desired Return on Investment.

- Automation (CapEx) vs. Labor Costs (OpEx).

- Environmental Requirements.

- Zoning Restrictions.

- Any other variable that needs to be considered for the site.

3. Cement Import Termianl Options

3.1. Flat Storage Option

The Cement Flat Storage provides an excellent solution for a low-CapEx storage. Certain factors need to be considered and weighed to determine if a Flat Storage is desirable:

-

- Labor costs.

- Lease costs.

- Availability of sufficient land area.

- Lower CapEx is a requirement for project approval.

- Compartmentalizing.

- Flexibility with expanding capacity.

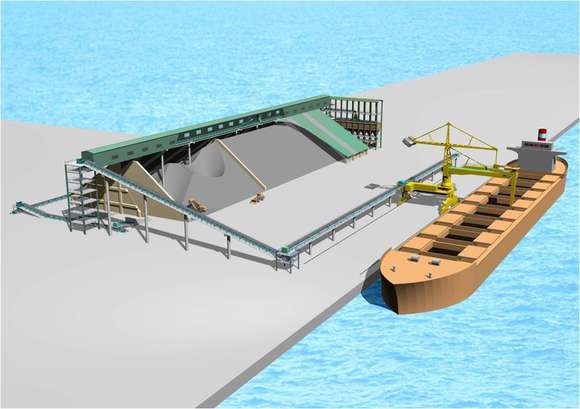

Figure 1. Typical Flat Cement Storage with Front-End Loader Reclaim

Reclaim for Flat storage can be handled in several ways. If labor costs are low, it would be preferable to have front loaders that feed a hopper and bucket elevator to fill the truck loadout bins. In locations where labor costs are extremely high, there may be value in the installation of fluidized flooring.

Figure 2. Reclaim for Flat Storage

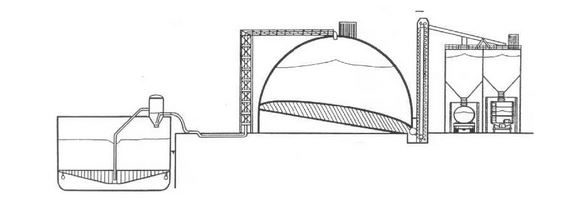

3.2. Dome Storage Option

Domes provide a good solution for a fully automated operation. There are various configurations that can be designed for specific operational needs. The capital expenditure is expected to be higher than that of a flat storage, but there are benefits of a Dome Storage such as:

-

- Large live storage capacity.

- Full Automation.

- Reduced labor costs.

- Smaller footprint.

Figure 3. Typical Dome Storage System

In cases where multiple products are required or deliveries need to be kept separate, multiple domes or combination of dome and silos would need to be considered.

Figure 4. Typical Cement Dome Storage

3.3. Silo Storage Option

Typically, a silo storage is a preferred method for dispersing product to local markets that cannot be accessed by large bulk carriers. Silo storages are only seen along rivers and lakes where small 5-10kton barges are used for transporting from a production plant. One of the benefits of this type of storage is that it takes up a very small footprint; however, the capital cost to build per ton of storage capacity is the highest.

Figure 5. Cement Silo Storage with Truck and Rail Disbursing

3.4. Floating Storage

Converting an older bulk carrier into a floating storage is a low-cost storage option, however not all ports are warm to this concept. The ship unloader can be mounted on rails on the vessel deck and used to unload from the incoming vessel as well as to withdraw from the floating storage to the truck-loading bins on shore. Either a Handymax or Supramax ship could be converted and designed for a storage capacity of 40,000-50,000 metric tons in 5 or 6 compartments (holds). This is by far the most economical option.

It’s important to begin early discussions with the local port authorities to discuss this option before making any investment. A permanent berthing space would need to be obtained from the Port Authority within a reasonable distance (300 m or less) from the truck loading bins on shore.

Figure 6. Floating Storage Example

Figure 7. Floating Pipeline to Truck Loading Bins

3.5. Unloading Equipment

Bulk carriers can be unloaded through various methods. The two preferred methods are by either screw or pneumatic conveying. Typically, screw to belt is common on docksides where fixed equipment is allowed which represents an overall lower Operation cost to unloading. Pneumatic is preferred in cases where the dock face is considered to be shared and unloaders, whether mobile or barge mounted, must be moved after unloading operations have been completed.

Figure 8. Barge Mounted Unloader

Some of the major considerations for ship unloader selection and design are:

-

- Reach requirements.

- Rate of unloading.

- Distance of transport.

- Mobility needs.

Figure 9. Floating Storage Rail Mounted Unloader

Ship unloading manufacturers can create custom solutions, however, it is important to understand that keeping the design as standard as possible offers cost savings to the project.

Figure 10. Dockside Screw Rail Mounted Unloader

Figure 11. Pnuematic Rail Mounted Unloader

About the Author(s)

Christian Benavides

Mr. Benavides has over 20 years’ experience in Project Management and on-site installations. He has worked in multi-cultural, heavy industrial environments, which has provided him with disciplined management skills for personnel and projects. His skills include capital cost estimating, project scheduling, project planning and control. His experience also includes the management and supervision of protective coatings installations. Mr. Benavides has a degree in Architectural Design from the University of Arkansas, Fayetteville, AR, and an Associates in Construction Management from St. Louis Community College, St. Louis, Missouri.

PEC Consulting Group LLC | PENTA Engineering Corporation | St. Louis, Missouri, USA

How can we help you? Get in touch with our team of experts.